Brackett Machine Co. Inc.

Committed to Quality

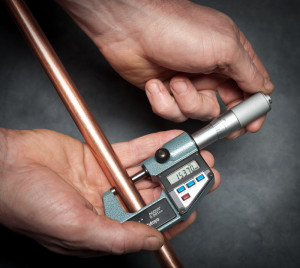

Only the finest quality raw materials are used throughout. Inner production gas tubes are drawn to tolerances of thousandths, and only the industries best drawn stainless is used to insure each and every Tuyere is to exact tolerances required.

Internal solder joints have been replaced with technology's finest advancements. These new joints have been heat tested to 1000 degrees F, vibration and pressure tested to 6000 P.S.I. and has proven superior to the stress and harmonic tendency they must withstand during a campaign of maximum duration.

Another advanced technology is Brackett 's Flow Control System. Now vessles are C.F.M. matched, resulting in uniform nurdle formation and even burn back. Each Tuyere is flow and leak tested at 100 P.S.I.G. on laboratory quality equipment prior to leaving the Brackett Machine facilities. Each unit is then matched and tagged with the flow readings, and sent along with a report of the results for the entire shipment.